About Ferret

At Ferret, we do more than send metal stock through our roll stations. We partner with our clients to provide them with the best roll-forming options. We shape metal through a series of steps and stages until we can reach the desired look and output.

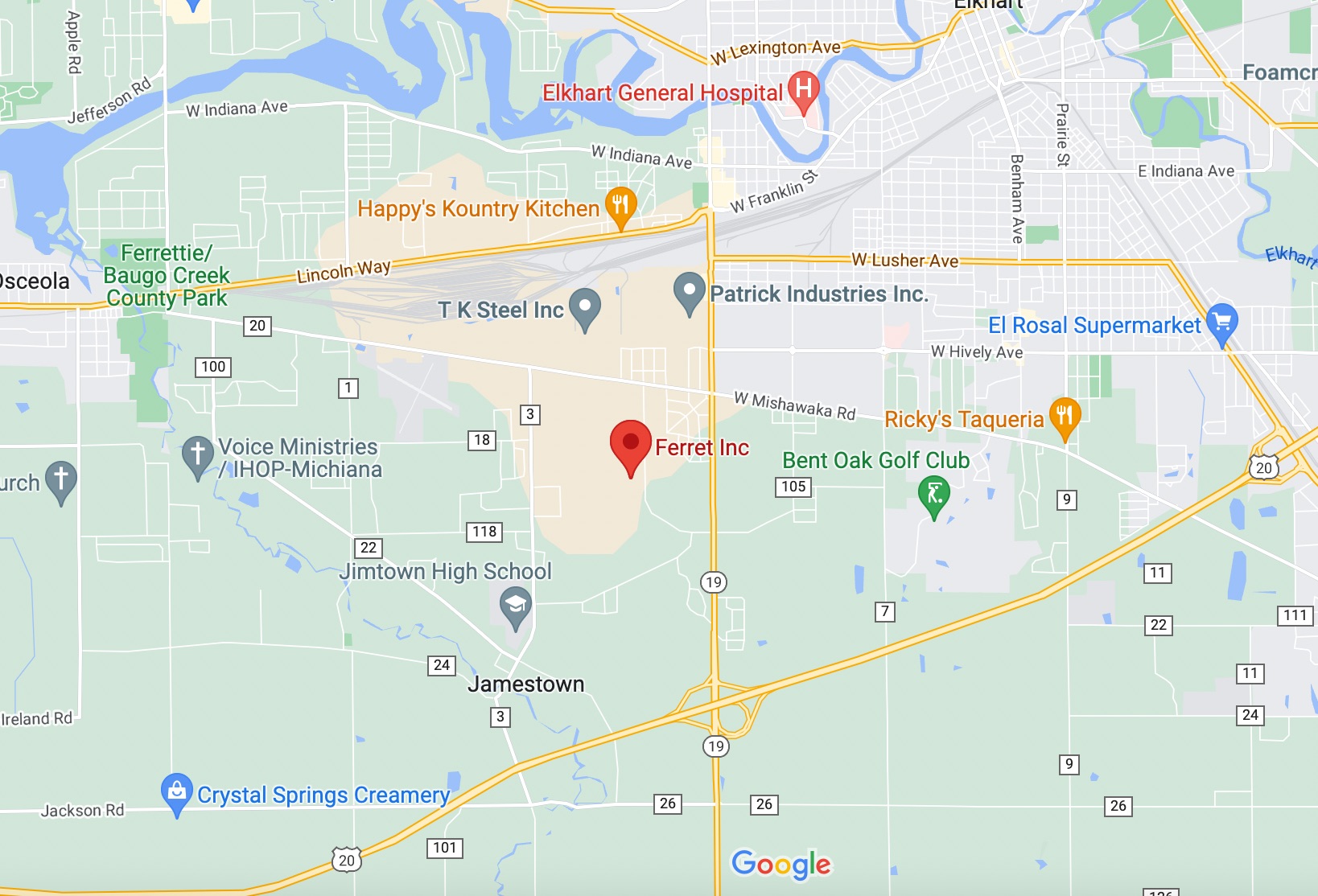

Ferret operates out of Elkhart, Indiana where we call the Midwest home! We are centrally located to raw materials and have access to all major transportation options, contributing to our ability to provide low costs for material procurement and help maintain rising freight costs.